Gefco / American Augers VR-500 Drill Rig

Gefco / American Augers VR-500 Drill Rig

Location:Woodward, OK

Jerry Steed

Description

American Augers Used VR-500 Standard Oil and Gas Drilling Rig

2008 Serial Number VR500001108

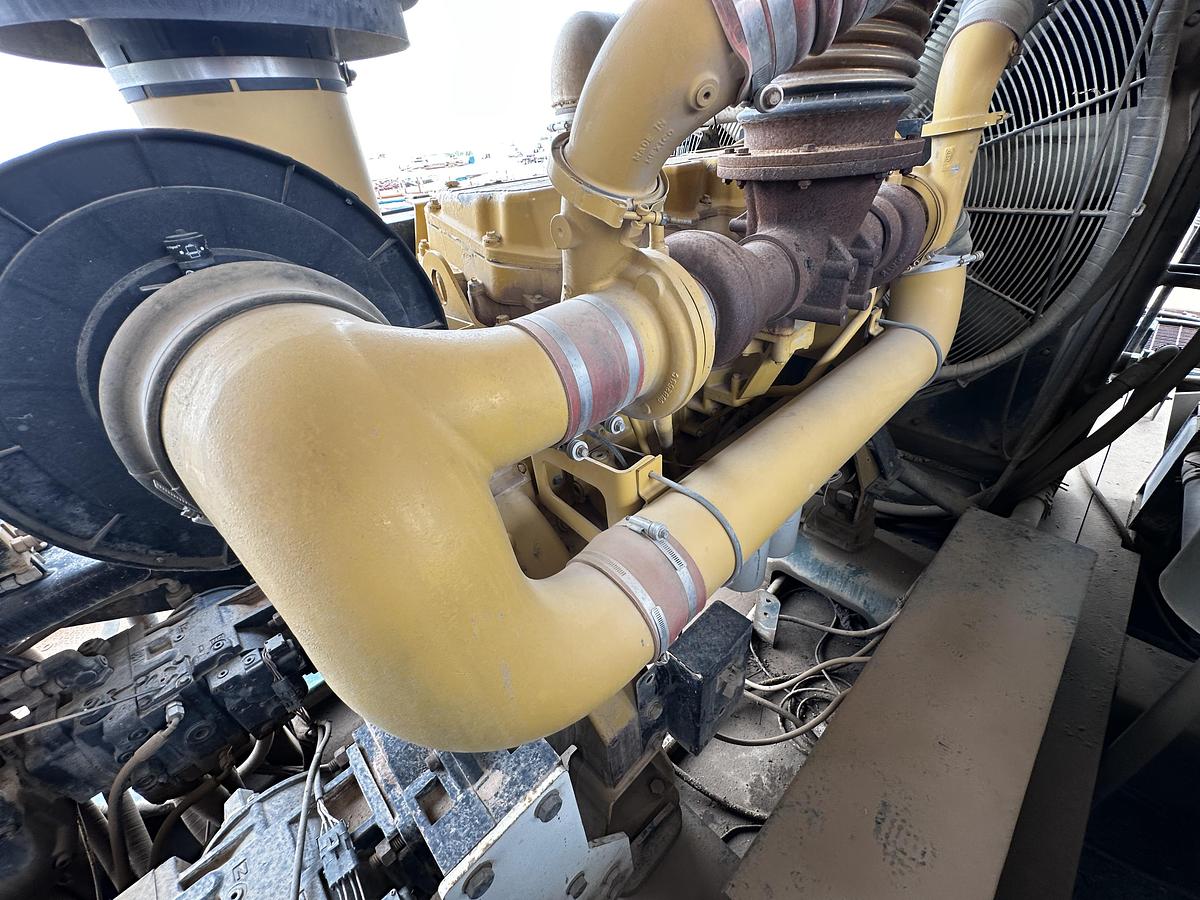

Cat C18 Diesel Engines

Safe Working Load Rating:

500,000 lbs (250 Tons) 450,000lbs below hook

1. Built to API Spec 4F Specification for Drilling and Well Servicing Structures

2. Canadian Drill Rig Standard

Stabilization:

1. Two struts between the Derrick and the trailer are the safety supports on the

back side of the Derrick.

2. Trailer has 4 jacks – 2 at the rear of the trailer and 2 toward the gooseneck

transition. There are 4 non-hydraulic screw jacks permanently welded into the

trailer – 2 at the tilt cylinder attachment point and 2 at the rear of the trailer to

handle half of the drilling forces. 2 additional screw jacks are on the substructure

beam that carries the other half of the drilling forces.

3. Drill Rig mounted on Triple-axle trailer, air ride suspension. Comes with a Tandem Stinger axle for

Transportation on roads.

4. 10’Max Overall Transport Width

5. The trailer jacks raise the rig enough to provide about 8’ of clearance below the drilling floor.

Derrick:

1. Space Frame construction made mostly of plate having triangulated lightening

holes where possible. The design will not require a truss for stiffness.

2. Removable 15ft rear section allows shorter transport length.

3. Designed to operate only in the vertical position

4. Range III drill pipe compatible length

5. 50’ of total carriage travel.

6. Ladder – full length with harness attachments.

7. 2 Telescopic cylinders are used to raise the Derrick. Load check valves are

integrated into the cylinders. A third cylinder (single stage) has a cable attached to

the rod end and controls the Derrick when it is nearly vertical. It will prevent

the telescopic cylinders from undergoing an overrunning load.

8. 2 winches are provided at the top of the Derrick

Drill Pipe Handling System:

1. Swing arm type of handling apparatus with opposed jaw grippers that roll 180 degrees.

2. Alignment is by patent pending American Augers floating assembly which ensures reliable

alignment of pipe.

3. The pipe handler is powered by the rig.

4. The controls are electric over hydraulic with sufficient cabling to operate from the driller’s cabin

5. Suitable for 2 7/8” drill pipe to 8” collars & 9 5/8 casing – max load 3500lbs.

Drilling Floor and Support Beam:

1. Drilling structure has a steel floor covered in Hi-Vis Anti Skid plastic Trac Mat

A slip bowl attaches to floor

2. The rear of the trailer and drilling floor is supported by a deep beam that attaches

to the back of the trailer structure. The beam has screw jacks at each end which

conduct the load against 6’ x 6’ ground platforms.

3. (14’) of approximate vertical clearance from the ground to the bottom of the drilling floor.

4. The drilling floor is 1⁄4” diamond plate and is supported by tubular braces that are pinned in place.

5. The slip assembly is hydraulically powered and is controlled from the cabin.

Carriage:

1. Rack and pinion carriage drive - Six (6) pinion

2. 500,000 lbs. @ 44 FPM in max pull mode

3. 200,000 lbs, @ 125 FPM in max speed mode

4. Infinitely adjustable pull down and pullback force limiter

5. (6ea) brakes are spring set hydraulic release type.

6. Rack and Pinion design

7. Hook devices have triple roller design at top front and bottom rear.

8. Powered greaser lubricates the pinions periodically

9. Powered greaser for drill pipe threads is remote control.

Rotary Drive:

1. Top head type with slip spindle and slip sub

2. 30,000 ft-lbs max rotary torque

3. (95) RPM max rotary speed

4. Digital rotary tachometer

5. Dual pinion drive

6. Rotary brakes between rotary motors and planetaries

7. Slip Spindle with 5-1/2” API-FH tool joint connection

8. 3" (76mm) fluid course in the rotary spindle, 4” 5,000psi swivel hose

9. Infinitely adjustable torque limiter

Wrenches:

1. Open Side type with opposed jaw design using 8” clamp cylinders

2. Hydraulically moveable to allow clearance from the drill string

3. Entire assembly can move 12” upward using cylinder power.

4. Clamps roll on cam followers

5. Quick Change Die Holders

6. Max. breakout torque, 60,000 ft-lb

7. Max. makeup torque, 60,000 ft-lb

8. Grip range – 4 1/8” to 14 3/4”

9. 18 3⁄4 opening - the dies when retracted will provide at least 2” of clearance in all

directions from the largest casing.

10. Operator adjustable torque limiters for makeup and breakout functions

11. Remote control from cabin

12. Designed for easy removal and transport

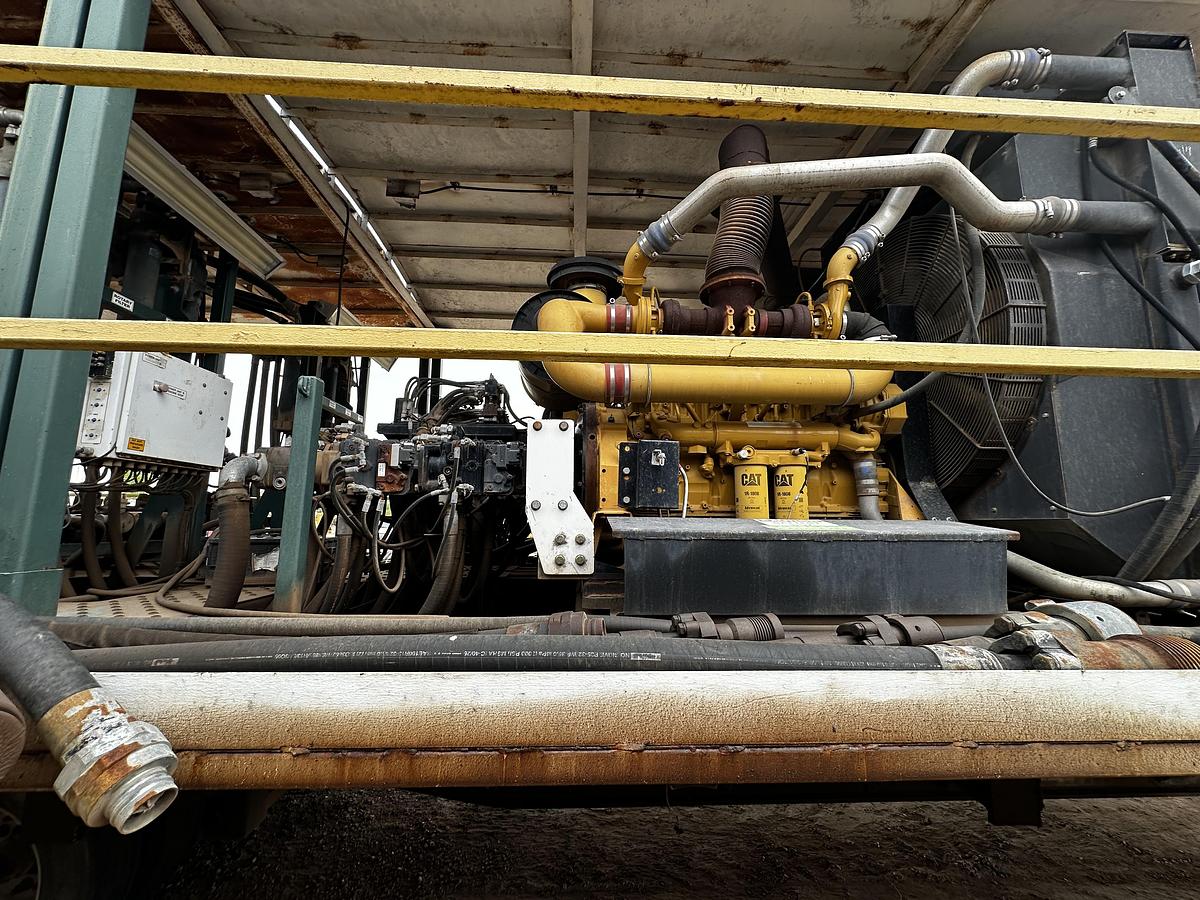

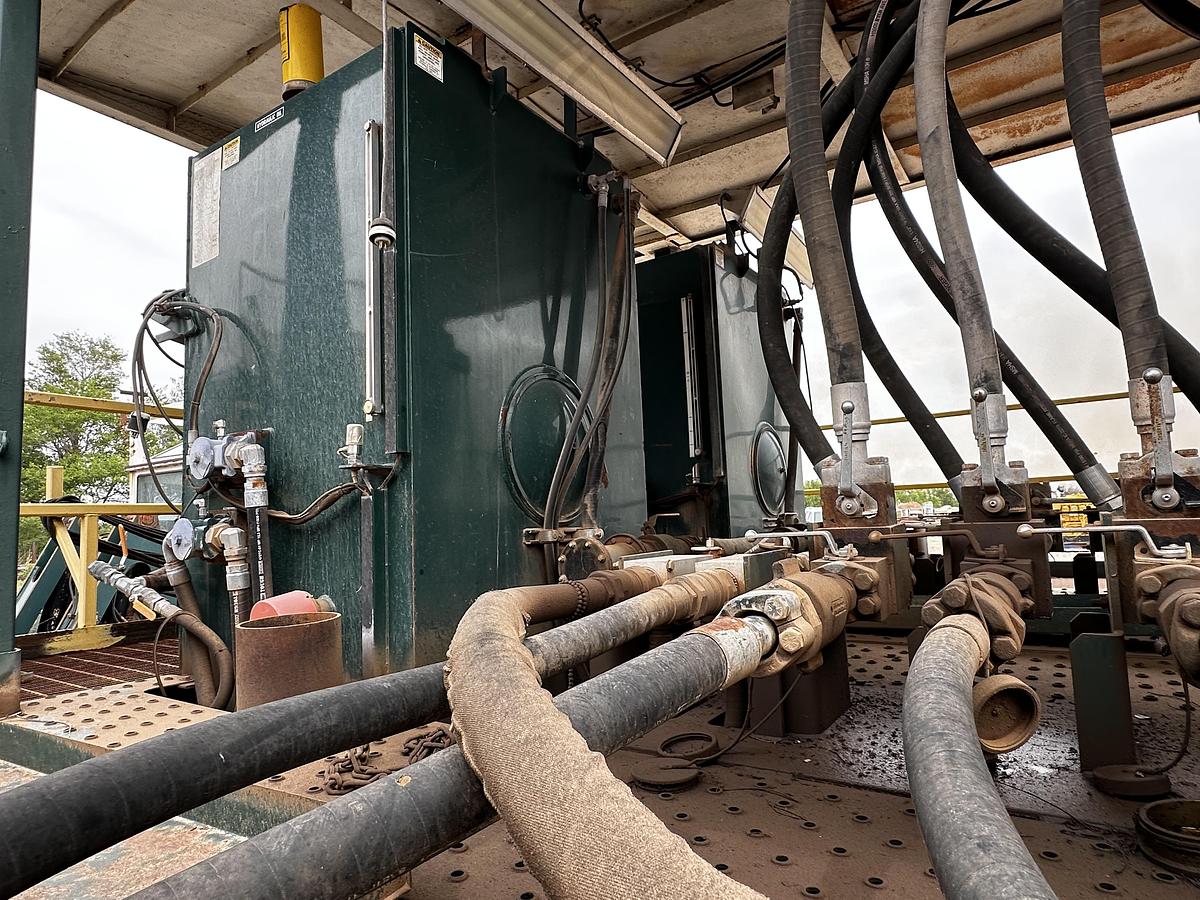

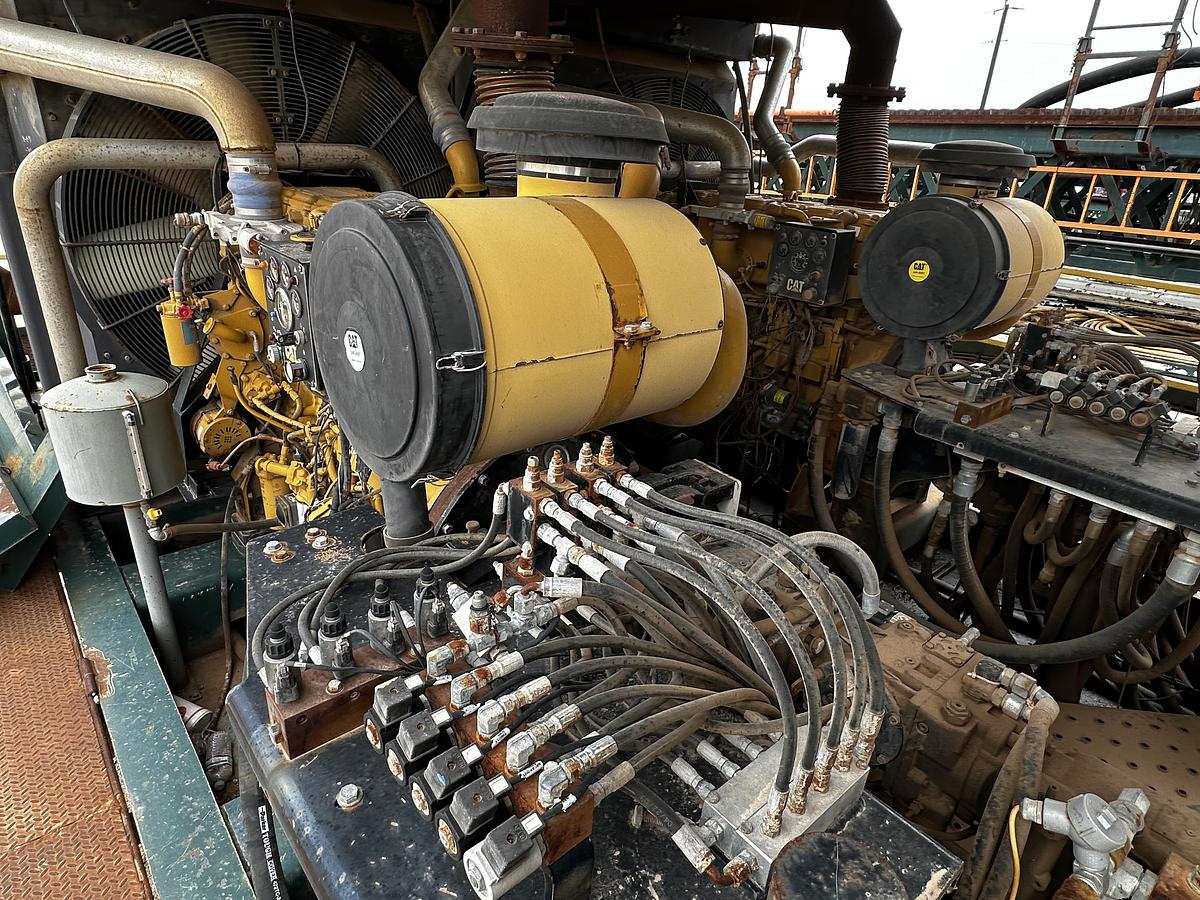

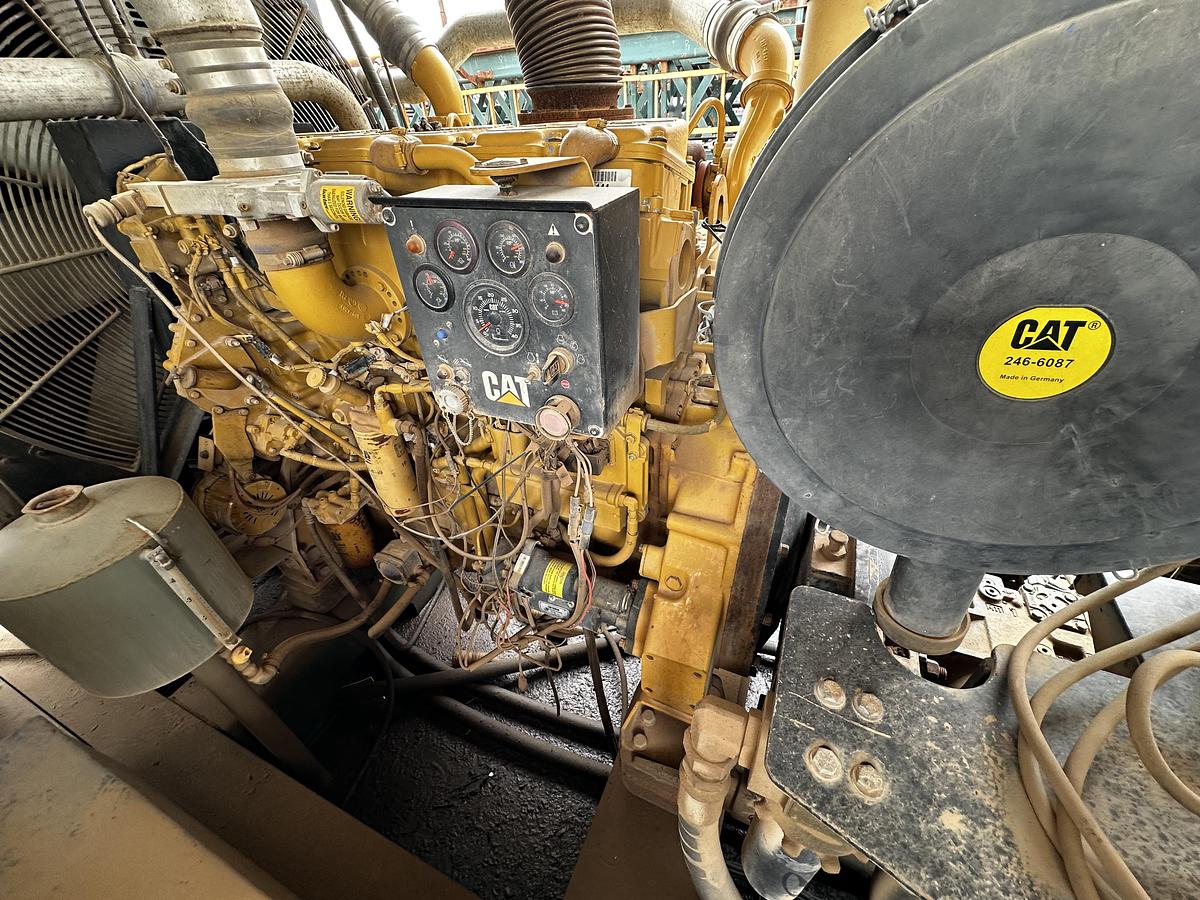

HPU, (Hydraulic Power Unit):

1. 1400 Total Horsepower - (2) Tier III Caterpillar C-18, 700 HP @ 2100 RPM (1100 hrs)

2. Positive air shutoff valve, each engine

3. Hydrostatic drive pumps

4. Pressure compensated piston pumps

5. Electrical power is not provided for anything such as external lighting, electric trash pump, etc.

6. The hydraulic and mud hoses are contained in a hose carrier.

7. Auxiliary hydraulic flow of 30 GPM is proportionally controlled from the cabin.

8. Hydraulic power for slips provided and controlled from cabin.

Operators Control Panel At Drillers Console:

1. Engine start/stop, throttle

2. Full proportional controls on rotary and thrust/pullback functions

3. Operator adjustable torque limiters for rotary and wrench makeup torque

4. Operator adjustable force limiters for thrust, pullback, and wrenches

5. Mud blow down valve

6. Rig mounted lights, electrical outlets, 110V

7. Fluorescent rig lights provided on cabin and Derrick, 110V

8. Programmable microprocessor controls main drilling functions

Electrical System:

Conforms to API spec 4F (not explosion proof)

Trailer:

Only 1 trailer is provided – the rig trailer, with a Tandem Stinger axle for road transport.

The pipe handler and the power units and the driller’s cabin do not come with trailers.

Rig trailer is gooseneck type with Triple axle and no on-board power.

HPU System:

(2) Cat C18 HPU mounted on 4 axle air ride trailer

Fuel Tank:

Day tank, mounted in HPU container, for setup, not intended to run rig at full power all day.

Driller’s Cabin:

20’ ISO container With Heat, Cooling, and pressurized air.

Controls:

Electric over hydraulic with a microprocessor and LCD screen for displaying system information.

Crane:

1 swinging crane is mounted at the top of the Derrick and has a 8000lb hydraulically powered

Winch mounted on the trailer deck.

Work Space:

2 sets of stairs are provided for access to the drilling floor and the driller’s cabin, walkways, landings and handrails are included.

Paint:

Green, White, Orange, Black

Specifications

| Manufacturer | Gefco / American Augers |

| Model | VR-500 Drill Rig |

| Condition | Used |

| Serial Number | VR5000011008 |

| Stock Number | 606710 |